Overview

Ennis-Flint is internationally known as one of the world’s most successful manufacturers and distributors of pavement marking materials with over ten production facilitates across the United States. They supply transportation departments in essentially every state with reusable containers of traffic paint. In order to maintain cleanliness and quality products, Ennis Flint designed an automated container washing process. At the end of the washing process, containers of paint-laden water were being stored until a proper disposal method could be identified.

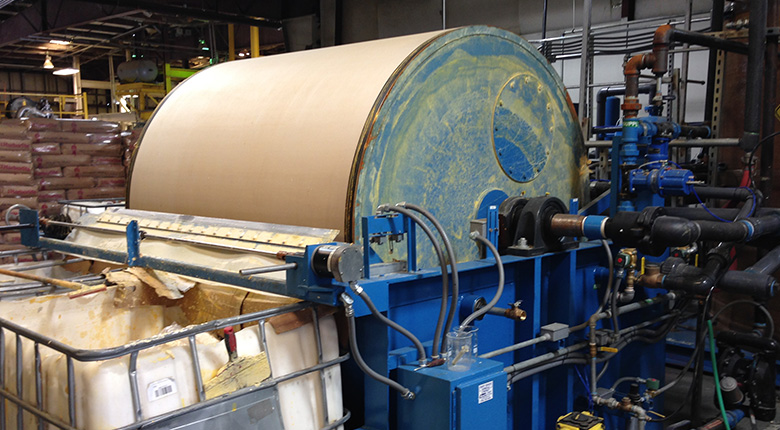

Timmons Group was hired to design an automated process that would effectively remove the paint from the wash water, allowing the water to be discharged to the local POTW (Publicly Owned Treatment Works). After in-depth research and studies of the current process, Timmons Group determined that a vacuum-assisted diatomaceous earth rotary drum filter would suit the client’s space and staffing needs while meeting the locality’s strict discharge limits. Timmons Group provided the treatment system design drawings, industrial discharge permitting assistance, and hands-on construction assistance.

Ennis-Flint was so impressed by this pretreatment option that they opted to purchase three of these units. One for each of their facilities in Richmond, VA., Salem, OR, and Bakersfield CA.